The purpose of depackaging technology is so that food waste processors can accept packaged food onto their sites and process them through composting and anaerobic digestion after removing the outer packaging.

Food waste depackaging equipment.

Operators may find that using this technology could allow them to take packaged food waste as an input.

Food waste depackaging.

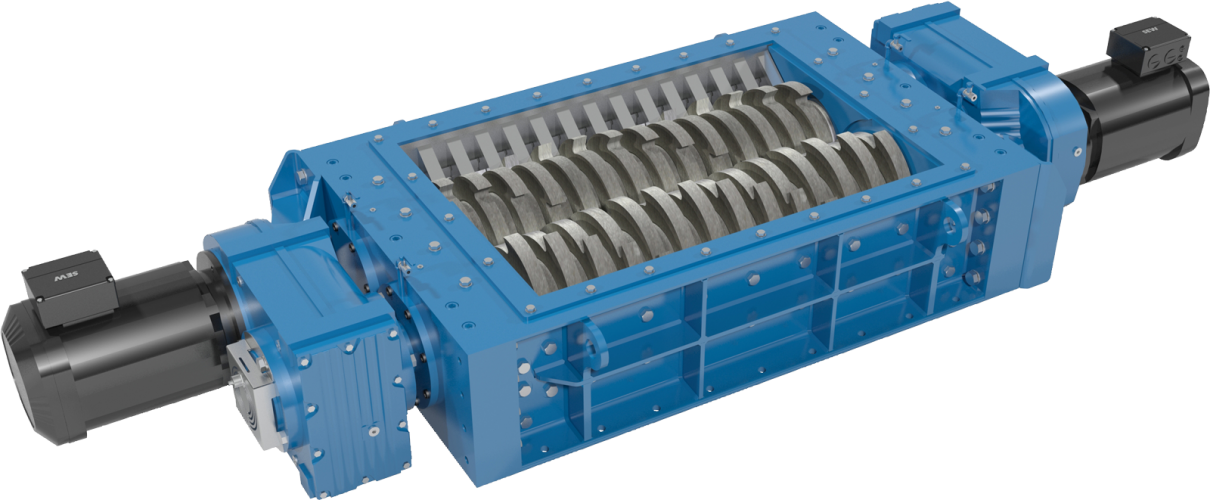

The dominator depackaging machine uses a motor to drive a solid steel shaft lined with paddles using mechanical and centrifugal forces material is depackaged and forced through a mesh screen.

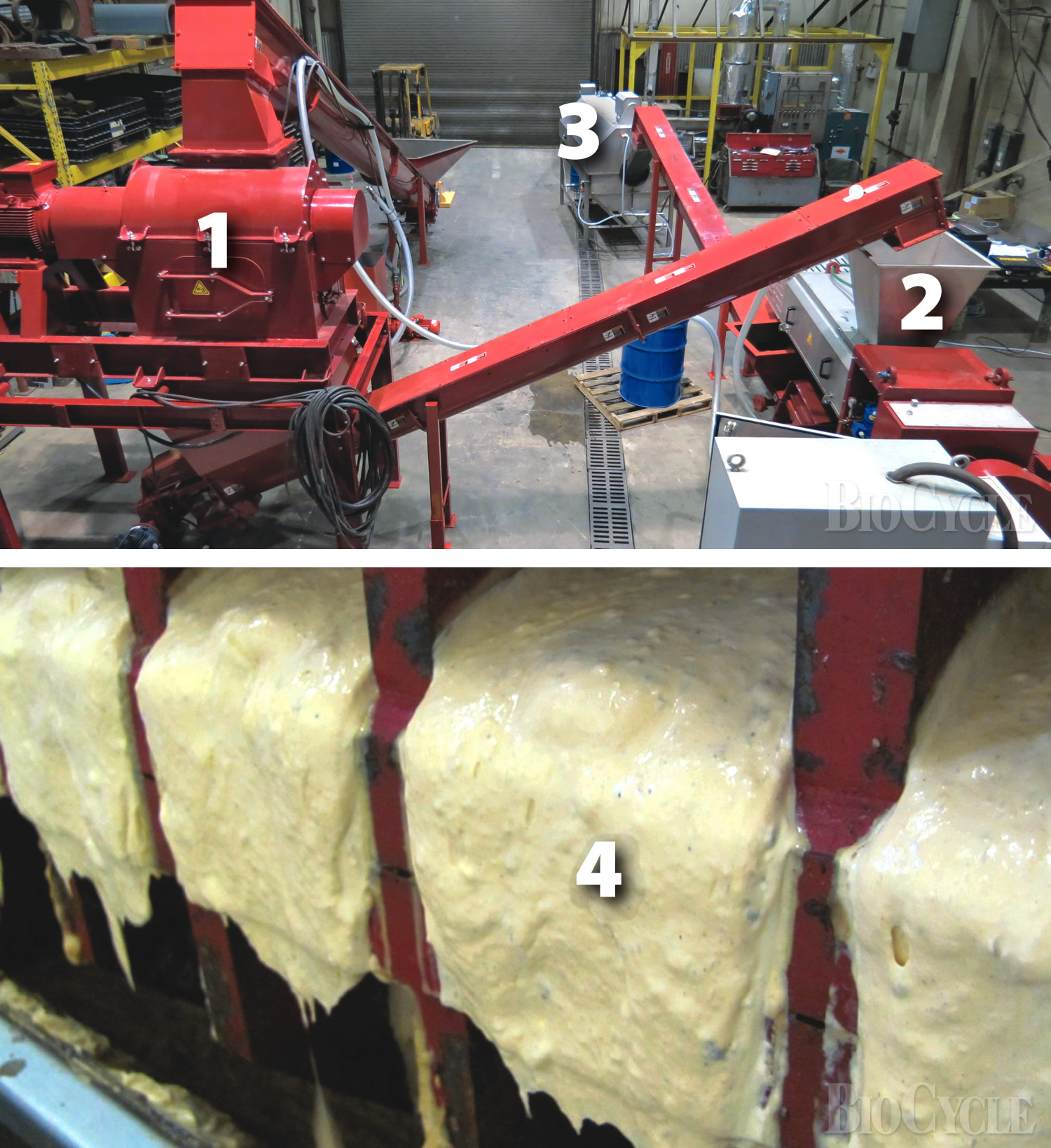

The machine and associated depackaging equipment is also able to depackage wet waste.

Food waste depackaging equipment.

Produces clean organic above 99 5 and.

Separated packaging can also then be sent for recycling further saving waste and potentially.

The waste depackaging process is key in getting suitable food waste material into anaerobic digestion plants and also used in putting food back into animal feeds.

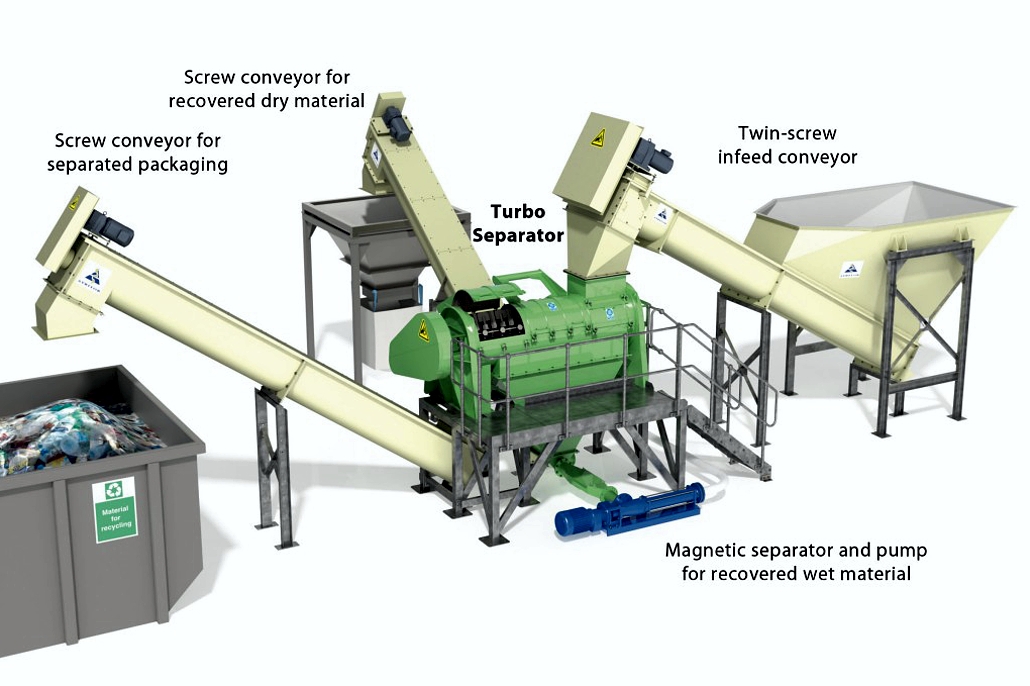

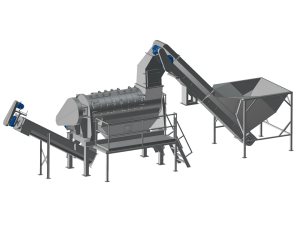

The scott equipment turbo separator is the world s leading large volume preprocessing and depackaging machine for source separated organics.

Food and materials handling waste depackaging equipment machines mixing hoppers waste handling consultancy from biomass engineering ltd uk.

The dupps food waste depackaging system separates organic from non organic materials including packaging materials such as plastics and paper.

Our systems are sold for use to produce biogas in anaerobic digestion system.

The waste depackaging process is key to getting suitable material into anaerobic digestion plants and also used in putting food back into animal feeds.

Our four main turbo separator models are thor and mega thor t42 t30 and t20.

The turbo separator system is simple in design efficient to use and operate.

Mavitec s paddle depacker model s handles your supermarket restaurant and kerbside waste.

The dominator waste depackaging machine is ideally suited for this application.

It s ideal for turning food processing supermarket and restaurant waste streams and any other food items suitable for recycling into profitable value added product.

It is built with either carbon or stainless steel for the toughest of applications.

Waste packaging makes its way through the barrel and out through the outlet.

Extremely effective at depackaging food waste it can process a wide variety of dry wet and every substance in between.