They are used in devices those we use on a daily basis from phones to computers.

Flex circuit design guidelines.

Build a flex circuit mock up the dynamic nature of flex circuits allows for a multitude of design options.

With the use of sensors and technology in everything from mobile phones to refrigerators to automobiles to wearable medical devices circuit boards are a component in many different types of products.

To make your mock up follow these steps.

While using this guide keep in mind that the design information provided is only a suggestion.

We also encourage you to call one of our knowledgeable experienced applications engineers at any time during your design process.

The best method for determining the validity of your design is to create a physical flex circuit mock up.

In today s world of electronics any product with an on off switch contains a circuit board.

Figure 5 1 designing with a bias for copper improves the circuit s dimensional stability.

It may not be practical for all applications.

Each supplier may have its own set of design rules and recommendations.

In most cases we.

Understand that flex and rigid flex design rules are different.

Now flex circuits are found in nearly every industry.

For flex annular rings need to be larger for flex rather than rigid.

Designing flexible circuits is sponsored by all flex.

The guidelines you need to design the best flex circuit for your product needs.

Successful flex circuit design guidelines.

The technical information details our standard manufacturing capabilities but note we also consider various flex designs that are outside of our typical.

Flexible circuits design guide.

Flex circuit guidelines conductor annular ring design and filleting all pads on both through hole and surface mounted pads should be filleted to reduce stress points.

Minco takes pride in manufacturing flex circuits that are considered difficult to build.

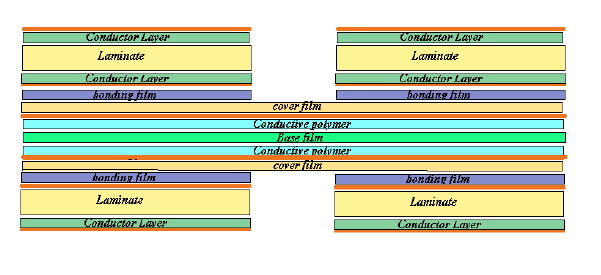

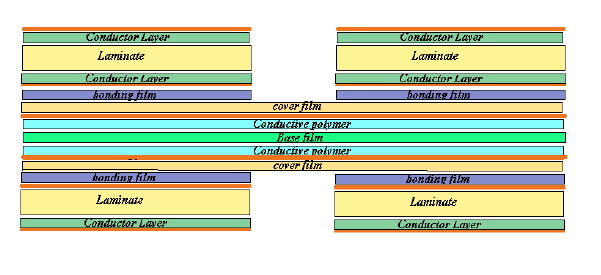

Flexible and rigid flex circuits are the building blocks of virtually various electronic products as they required durable reliable lightweight 3d circuitry.

Flex designs require button plating.

The course was written by john michael pierobon who has an advanced engineering degree from purdue university john michael has taught hundreds of technical courses throughout the world and speaks several languages fluently.

All flex design guide the all flex design guide is a significant tool that you will find very helpful in designing a highly reliable flexible circuit optimized for all flex manufacturability.

Flex circuit design guide the purpose of this design guide is to enable you to design a high quality manufacturable flexible printed circuit.

They stand ready to assist you at every step to ensure that your flex circuit design is a successful one.

We hope you find this flex circuit design guide a useful tool throughout your design process.