While using this guide keep in mind that the design information provided is only a suggestion.

Flex circuit design guide.

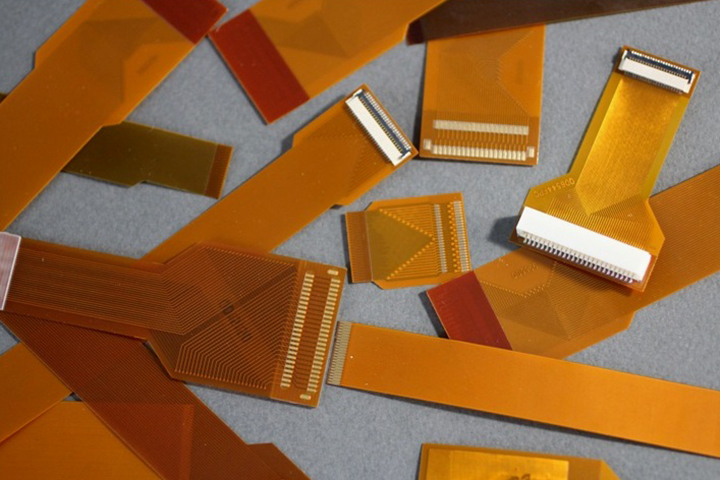

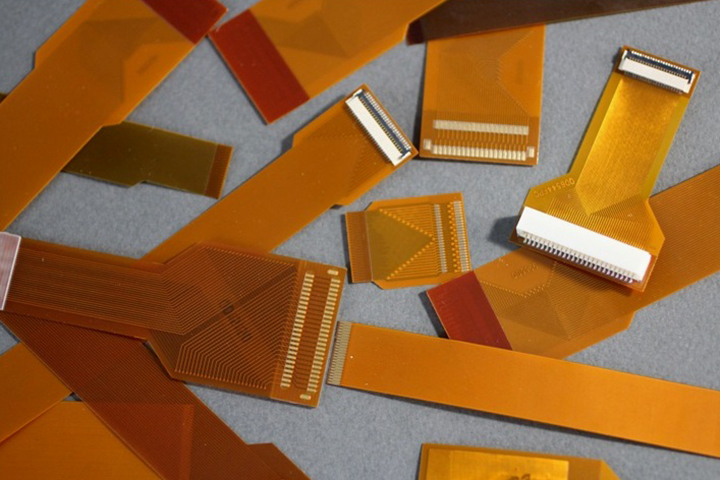

They are used in devices those we use on a daily basis from phones to computers.

Now flex circuits are found in nearly every industry.

All flex design guide the all flex design guide is a significant tool that you will find very helpful in designing a highly reliable flexible circuit optimized for all flex manufacturability.

We also encourage you to call one of our knowledgeable experienced applications engineers at any time during your design process.

Epec engineered technologies subject.

4 capabilities matrix circuit layer design guidelines nominal attribute detail minimum preferred line width outer layers a 0015 002 line width inner layers b 001 002 line to line space outer layers c 0015 002 line to line space inner layers d 001 002 pth diameter drilledengineering e 001 min pth to pth pitch center to center f ø 0065 ø 0075.

Flex rigid flex circuits can be shaped to fit where no other design can.

Flex circuit design guide author.

Tolerance setting flex circuit designs proper application of tolerances of ex circuit design features is a matter that concerns both the ex circuit manufacturer and the ex circuit user.

Heterogeneous system rigid circuit board wiring harness flex soldered in or plugged detachable.

Flexible circuits design guide.

The technical information details our standard manufacturing capabilities but note we also consider various flex designs that are outside of our typical.

In essence flexible circuits give you unlimited freedom of packaging geometry whi le retaining the.

Documents for manufacturing flex rigid circuit boards basically standards must be regarded such as ipc 2223 ipc 6013 the basic design guide from würth elektronik as well as variant specific design rules and our drying recommendations.

It may not be practical for all applications.

Flexible and rigid flex circuits are the building blocks of virtually various electronic products as they required durable reliable lightweight 3d circuitry.

In most cases we.

They stand ready to assist you at every step to ensure that your flex circuit design is a successful one.

They are a hybrid of ordinary printed circuit boards and round wire exhibiting benefits of each.

Minco takes pride in manufacturing flex circuits that are considered difficult to build.

Figure 5 1 designing with a bias for copper improves the circuit s dimensional stability.

Designing flexible circuits is sponsored by all flex.

The course was written by john michael pierobon who has an advanced engineering degree from purdue university john michael has taught hundreds of technical courses throughout the world and speaks several languages fluently.

The purpose of this design guide is to enable you to design a highly reliable flexible printed circuit optimized for manufacturability.

While using this guide keep in mind that the design information provided is only a suggestion.